INDUSTRIAL PROCESS AND COMMERCIAL VENTILATION SYSTEMS

ATEX (ATmosphères EXplosibles) is a conglomeration of European Union (EU) directives outlining equipment installed and operated in potentially explosive atmospheres. The ATEX directive coordinates various technical and legal conditions throughout Europe to ensure a high level of safety for the end-user by reducing the explosion risk through established design methods. Since July 1, 2003, equipment manufactured for operation in potentially explosive environments has been required to comply with the EU’s ATEX Manufacturer’s Directive (94/9/EC). The ATEX Directive applies to all countries in the EU and the European Economic Area (EEA)

Model EPFN High Efficiency Plenum Fan

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

BCN/HIB/BCS/TCBI Industrial Backward Curved Fans

12.25" to 90.75" wheel diameters Airflow from 700 to 291,400 CFM Static pressure to 100" w.g. Catalog: 330, 400, 1450 & 1100

TBNA/TBNS Turbo Pressure Blower

14.5" to 26.5" wheel diameters Airflow from 0 to 5,400 CFM Static pressure to 57" w.g. Catalog: 1250

Model RBO Industrial Radial Blade Fan

RBO/RBA/RBW Industrial Radial Blade Fan

8.75" to 104.25" wheel diameters Airflow from 185 to 141,800 CFM Static pressure to 32" w.g. AMCA licensed for Air Catalog: 902

MBO/MBR/MBW Heavy Duty Pressure Blower

19.63" to 58.94" wheel diameters Airflow from 300 to 20,000 CFM Static pressure to 180" w.g. Catalog: 1400

RTF/HRT Radial Tip Fan

20.5" to 90.75" wheel diameters Airflow from 2,760 to 254,700 CFM Static pressure to 36" w.g. AMCA licensed for Air (RTF) Catalog: 950 & 980

TVIFE Mixed Flow, Induced Flow

The TVIFE is an arrangement 4, direct drive, induced flow fan that utilizes a mixed flow wheel. The TVIFE housing uses an innovative Turbo-Vane™ design that integrates the internal nozzle and straightening vanes into one. Turbo-Vanes™ induce air within the fan housing as well as the windband, giving the best entrainment and efficiency in the industry. The design also allows for uniform motor cooling, while keeping the motor out of the airstream. Sizes are available from 12.5" up to 66" and capable of handling over 80,000 cfm. Twin City Fan & Blower model TVIFE is tested and certified in accordance with AMCA 260 (induced flow) for air and sound.

BAIFE/ BCIFE Centrifugal Induced Flow

The BAIFE utilizes a highly efficient airfoil bladed centrifugal wheel and is tested and certified in accordance with AMCA 260 (induced flow) for air and sound. Available in arrangements 1, 4, 8, 9 and 10. The BCIFE utilizes a backward inclined centrifugal wheel and is intended for high moisture and high temperature applications. The BCIFE is tested in accordance with AMCA 260 (induced flow) for air and sound. Available in arrangements 1, 4, 8, 9 and 10.

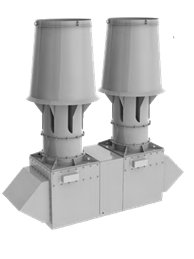

QIFE Mixed Flow, Induced Flow

The model QIFE is an arrangement 9 belt driven induced flow fan utilizing a mixed flow wheel. Sizes are available from 12.5" up to 66" and capable of handling over 75,000 CFM. The nozzle on the QIFE has a built-in drain pan to reduce potential rain entry into the building when the fan is not running. Twin City Fan & Blower model QIFE is tested and certified in accordance with AMCA 260 (induced flow) for air and sound.

QFE / TFE Mixed & Inline Centrifugal

The TFE is an arrangement 9 belt driven inline centrifugal fan that utilizes a high velocity discharge nozzle to achieve a high plume height. The TFE offers a gravity damper at the fan outlet for full positive shut-off when the fan is not in use, which prevents rain from entering the building. The QFE is similar in design, but incorporates a high efficiency mixed flow wheel design.

PETROCHEMICAL

Twin City Fan has earned a reputation for consistently delivering products that are specifically designed to meet the industry’s stringent requirements. Our heavy duty industrial fans are used in numerous petroleum refining, chemical/plastic production, and pelletizing processes and can be customized for virtually every application including flare stacks, thermal oxidizers, heating (fired heaters), combustion air, desulfurization, dryers, pollution control systems, material handling, and steam generation (boilers). Twin City Fan and its member companies have vast experience in meeting the extremely stringent requirements of the American Petroleum Institute (API). Typical Applications • ATEX • Boiler Systems • Dust Collection • Flue Gas Recirculation (FGR) • Forced Draft (FD) • Induced Draft (ID) • Desulfurization / Pelletizing • Fired Heaters - FD & ID • Flare Stacks • Oil and Gas Refining • RTO Systems • Combustion Air • Heating & Cooling • Pneumatic Conveying / Pressurization .