Tube Ice Machine

Ice Tube Maker | Thermojinn Tube Ice Maker | Machine Tube Ice: Create Delicious and Refreshing Ice Tubes

ICE TUBE Maker is a revolutionary product that can make ice tubes quickly and easily. It is an innovative device that helps you create delicious and refreshing ice tubes in no time. With ICE TUBE Maker, you can make different shapes and sizes of ice tubes for your favorite drinks. The device is easy to use, making it ideal for everyone from experienced bartenders to home users who want to make their own unique frozen treats. With its sleek design and user-friendly features, ICE TUBE Maker makes creating delicious ice tubes easy and fun.

Ice tube maker is a modern appliance that makes cylindrical-shaped ice cubes. This type of ice cube is perfect for use in drinks and cocktails, as it melts slower than traditional ice cubes.

The process of making ice with an ice tube maker is simple. Water is poured into the machine, which then freezes the water into cylindrical-shaped ice cubes. The ice cubes are then released into a container where they can be easily accessed.

Plate Ice Machine

Ice machine evaporator plate is an essential component of any ice machine. It is responsible for the actual freezing process that turns water into ice.

The evaporator plate consists of a series of thin, flat metal plates that are arranged in a grid pattern. These plates are cooled by a refrigerant, which causes any water on the surface of the plates to freeze.

There are several types of evaporator plates used in ice machines, including tube-and-shell, plate-and-frame, and plate-and-fin designs.

Tube-and-shell evaporator plates consist of a series of tubes that are surrounded by a shell. The refrigerant flows through the tubes, while the water to be frozen flows over the outside of the tubes. Plate-and-frame and plate-and-fin designs use thin metal plates that are stacked together to create a large surface area for heat transfer.

Proper maintenance and cleaning of the evaporator plate is crucial for the efficient operation of the ice machine. Over time, mineral deposits can build up on the surface of the plate, reducing its ability to transfer heat.

To clean the evaporator plate, it should be removed from the ice machine and soaked in a solution of water and a mild detergent. Any mineral deposits can be scrubbed away with a soft brush or sponge. After cleaning, the plate should be rinsed thoroughly and allowed to dry completely before being reinstalled in the ice machine.

In recent years, there have been significant advancements in evaporator plate technology that have improved the efficiency and performance of ice machines.

One such advancement is the use of microchannel evaporator plates, which feature a series of small channels that increase the surface area available for heat transfer. Other advancements include the use of alternative refrigerants and the development of more durable and corrosion-resistant materials for the plates.

Ice machine evaporator plates are a critical component of any ice machine, responsible for the actual freezing process that turns water into ice.

Proper maintenance and cleaning of the evaporator plate is crucial for the efficient operation of the ice machine, and advancements in evaporator plate technology have led to improved efficiency and performance.

Flake Ice Machine

Flake ice machines are essential for businesses that require a constant supply of fresh ice. Whether you own a restaurant, a hotel, or a fishery, flake ice machines can help you meet your daily demands. A flake ice machine produces small, soft flakes of ice that are perfect for food displays, seafood storage, and beverage cooling.

If you’re in the market for a flake ice machine, you’ll find a wide range of options available. From compact countertop models to large industrial machines, there’s a flake ice machine for every business size and budget.

One of the biggest advantages of using a flake ice machine is its ability to produce soft, malleable flakes of ice. This type of ice is ideal for food displays, as it molds around products without damaging them. Flake ice also melts more slowly than other types of ice, keeping food and drinks cold for longer periods.

Another benefit of using a flake ice machine is its energy efficiency. Compared to other types of ice machines, flake ice machines use less water and energy to produce ice. This can translate into significant cost savings over time.

When choosing a flake ice machine, there are several factors to consider. First, you’ll need to determine the size and capacity of the machine that best suits your needs. Consider the amount of ice you’ll need to produce on a daily basis, as well as the available space in your business.

Other important factors to consider include the type of refrigeration system, the level of noise produced by the machine, and the ease of maintenance. Look for a machine with a durable construction and easy-to-clean components to ensure longevity and efficient operation.

Proper installation is crucial for ensuring the optimal performance of your flake ice machine. It’s important to follow the manufacturer’s instructions carefully and to have the machine installed by a professional if necessary. This will help prevent damage to the machine and ensure safe operation.

Regular maintenance is also essential for keeping your flake ice machine in good working condition. This includes cleaning the machine regularly, checking for leaks, and replacing worn or damaged parts as needed. By following these simple steps, you can extend the lifespan of your flake ice machine and avoid costly repairs down the line.

Block Ice Machine

Block ice is the ice made in the ice mold. It is hard, not easy to melt, has a long storage time and is convenient to transport. It is widely used in the field of food, fresh-keeping and cooling of aquatic products, ice sculpture and other special fields. It is the first ice used by humans.

1. Applying Modular design,Small footprint and simple on-site installation.

2. PLC control, automatic water replenishment, deicing and Ice delivery(optional), simple operation and low failure rate.

3. It can provide designed ice storage, ice delivery and ice breaking systems to save manpower and improve efficiency.

4. Not use coolant, no brine, no strong corrosion.

△ Ice making evaporator module

Ice cans : High quality aluminum alloy ice cans, galvanized or stainless steel support frame, made of clean and sanitary ice blocks, which can

be directly eaten.

Water input system : The specially designed water adding device is simple to operate, accurate to control the amount of water added, and avoids water

waste.

Defrosting system : Hot fluorine defrosting system, soft hot gas supply, efficient deicing, and no damage to the ice surface.

Ice dropping system: Manual / automatic hydraulic deicing lifting platform, simple and stable operation, safe deicing and non fragile.

△ Compressor unit module:

• compressor – Bitzer/Hanbell/Frascold/XM/Mycom and etc.

• Vessels – liquid receiver, oil separator (when needed), suction accumulator;

• Piping – suction and discharge;

• Valves – Danfoss/ AMG

• Control Panel – ThermoJinn

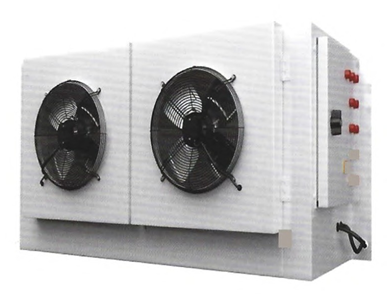

△Condensing module.

• Water cooling tower or

• Evaporative condenser or

• Air-cooled condenser

Reciprocating compressor Cylinder 4 Nos Capacity 3HP- 35HP

Thermojinn Semi-hermetic Single stage piston compressors are widely used not only in commercial and industrial refrigeration,but also in certain special air conditioning conditions. Thermojinn BV&BW Series compressors have a wide applicability, good in various refrigeration conditions.Despite the already mature and reliable technology in making piston compressor, Thermojinn still diligently researches and innovates to further improve the piston compressors’ performance such as quality and reliability. Thermojinn BV&BW Series include 31 models, with 4,6 cylinders, rated power ranging from 3 to 50HP, displacement from 18m³ to 154m³.

Compressor Features:

1. High quality cast iron for compressor house ,operating pressure can reach as high as 28 bar.

2. Suction Filter, check valve, temperature sensor are integrated into one, and the overall size of the compressor is small.

3. With the crankshaft designed by Thermojinn, the operation is smooth and with low-vibration.

4. High efficiency, high strength, low vibration,low gas pulsation and low noise, which is achieved through new technology,overall performance has reached the world top level of the same type of compressors.

5. Cooling capacity can be controlled according to different loads.

6. Motor protection module with 6Nos of temperature sensors.

7. The embedded safety valve joins the high pressure side and low pressure side to prevent the internal pressure from exceeding the safety threshold.

8. Using suction side refrigerant gas to effectively cooling down the motor, reduce additional energy consumption.

Reciprocating compressor Cylinder 6 Nos Capacity 25HP- 50HP

Thermojinn Semi-hermetic Single stage piston compressors are widely used not only in commercial and industrial refrigeration,but also in certain special air conditioning conditions. Thermojinn BV&BW Series compressors have a wide applicability, good in various refrigeration conditions.Despite the already mature and reliable technology in making piston compressor, Thermojinn still diligently researches and innovates to further improve the piston compressors’ performance such as quality and reliability. Thermojinn BV&BW Series include 31 models, with 4,6 cylinders, rated power ranging from 3 to 50HP, displacement from 18m³ to 154m³.

Compressor Features:

1. High quality cast iron for compressor house ,operating pressure can reach as high as 28 bar.

2. Suction Filter, check valve, temperature sensor are integrated into one, and the overall size of the compressor is small.

3. With the crankshaft designed by Thermojinn, the operation is smooth and with low-vibration.

4. High efficiency, high strength, low vibration,low gas pulsation and low noise, which is achieved through new technology,overall performance has reached the world top level of the same type of compressors.

5. Cooling capacity can be controlled according to different loads.

6. Motor protection module with 6Nos of temperature sensors.

7. The embedded safety valve joins the high pressure side and low pressure side to prevent the internal pressure from exceeding the safety threshold.

8. Using suction side refrigerant gas to effectively cooling down the motor, reduce additional energy consumption.

Two-stage reciprocating compressor Cylinder 4&6 Nos Capacity 8HP- 30HP

Thermojinn Semi-hermetic Two-stage piston compressors BSV&BSW Series includes 6 models. High-pressure displacement from 18-50.5 m³/h, Motor power :8-30HP. Applicability:R22,R404A and R507a. High efficiency, long durability,compact size and low vibration. The Two-stage compressor displacement is achieved through two consecutive compression. In First stage, the refrigerant gas from the evaporator is sucked from the inlet into the intermediate cavity. In second stage, the refrigerant gas is sucked in from the intermediate cavity and is compressed to the displacement pressure. Compared to the single stage compressor, the compression ratio of each stage of the Two-stage compressor is always lower. As a Result, the displacement temperature is lowered and efficiency is improved.

Compressor Features:

1: Operating pressure can reach as high as 28 bar.

2: Reliable valve plate design; impact resistant spring steel is used to make the valve plate.

3: Minimum space requirement, compact design, Easy maintenance.

4: Low vibration and noise. Cylinder combination of “4+6”, optimized mass balance design renders quiet running.

5: High cooling capacity and low energy consumption.

6: High reliability actuator:

a. The hardened surface of the eccentric shaft and crankshaft.

b. Large capacity oil pump.

c. Low friction bearing bush and aluminum piston.

d. Hard chrome plated piston ring.

7. Installed subcooler can further improve the compression efficiency.

Screw compressor, Capacity 40HP -160HP

Thermojinn Semi-hermetic screw compressors are widely used not only in commercial and industrial refrigeration,but also in certain special air conditioning conditions. Thermojinn SRC Series compressors have a wide applicability, good in various refrigeration conditions. Despite the already mature and reliable technology in making screw compressor, Thermojinn still diligently researches and innovates to further improve the screw compressors’ performance such as quality and reliability. Thermojinn SRC series include 15 models, rated power ranging from 40 to 60HP, displacement from 140m³ to 535m³.

Compressor Features:

1. Compact size, suction filter,check valve,and temperature sensor are all integrated into the compressor body.

2. Latest profile screw rotor with ratio of 5+6,high efficiency lubrication, perfect meshing between teeth, smooth and quiet operation.

3. Motor protection module provides reliable protection against motor high temperature, phase reversal and phase loss.

4. Suction & Discharge shut-off valves are able to reverse 360°,which is easily installed with flexibility.

5. Capacity control available with step and stepless , in line with full or partial load.

6. Using suction side refrigerant gas to effectively cooling down the motor, reduce additional energy consumption.

Monoblock unit A01W / Type Wall straddle / Capacity 1 HP- 4HP

A01W Wall straddle Monoblock & A01T Through wall Monoblock applies to various cold storages. The unit can be installed on the wall, and can be assembled with multi units stacked together.

Cases of the Monoblock are with Epoxy sprayed steel plates.

Hermetic piston compressors are applied, with R404A as the refrigerant.

STANDARD CONFIGURATION

○ Low noise Hermetic compressor

○ One time formulation casing for evaporator

○ Auto defrosting system

○ Condenser over-dirt alarm system

○ Condensate water evaporation tray

○ Expansion through capillary tube system

○ Filter on the liquid line

○ Cold room light and bulb

○ Cable for door micro switch

○ Cable for door switch heater on low temperature units

○ High- and low-pressure switches

○ Remote electronic control panel

Power supply:

230/1~/50

400/3N~/50

208-230/1~/60

230/3~/50

208-230/3~/60

440-460/3N~/60

440-460/3~/60

108-115/1~/60

Electrical accessories:

Prearrangement for supervision system

Accessories kit:

Audible and visual alarm

Remote control panel for 2-3-4 units

Condensation type:

Air + Axial Fan

Air + Centrifugal fan

City water with pressure valve

Winter Kit, low ambient temperature accessories:

Crankcase heater + Condenser fan pressure switch +

Double solenoid valve for defrosting

Crankcase heater + Pressure controlled condenser fan

speed regulator + Double solenoid valve for defrosting

Monoblock unit A01 R / Type Roof / Capacity 1.2HP – 6HP

A01R series Monoblock applies to cold storages with space available on the top.Cases of the Monoblock are with Epoxy sprayed steel plates. And conjunction partof evaporator and condenser unit is using insulated heat-rejected boxes. Hermeticpiston compressors are applied, with R404A as the refrigerant.

STANDARD CONFIGURATION

○ Low noise Hermetic compressor

○ One time formulation casing for evaporator

○ Auto defrosting system

○ Condenser over-dirt alarm system

○ Condensate water evaporation tray

○ Expansion through capillary tube

○ Filter on the liquid line

○ Cold room light and bulb

○ Cable for door micro switch

○ Cable for door switch heater on low temperature units

○ High- and low-pressure switches

○ Remote electronic control panel

OPTIONAL ACCESSARIES AND CONFIGURATION.

Power supply:

230/1~/50

400/3N~/50

208-230/1~/60

230/3~/50

208-230/3~/60

440-460/3N~/60

440-460/3~/60

108-115/1~/60

Electrical accessories:

Prearrangement for supervision system

Accessories kit:

Audible and visual alarm

Remote control panel for 2-3-4 units

Condensation type:

Air + Axial Fan

Air + Centrifugal fan

City water with pressure valve

Winter Kit, low ambient temperature accessories:

Crankcase heater + Condenser fan pressure switch +

Double solenoid valve for defrosting

Crankcase heater + Pressure controlled condenser fan

speed regulator + Double solenoid valve for defrosting

Monoblock unit A01 T / Type Through wall / Capacity 3.5HP – 13.5HP

A01W Wall straddle Monoblock & A01T Through wall Monoblock applies to various cold storages. The unit can be installed on the wall, and can be assembled with multi units stacked together.

Cases of the Monoblock are with Epoxy sprayed steel plates.

Hermetic piston compressors are applied, with R404A as the refrigerant.

STANDARD CONFIGURATION

○ Low noise Hermetic compressor

○ One time formulation casing for evaporator

○ Auto defrosting system

○ Condenser over-dirt alarm system

○ Condensate water evaporation tray

○ Expansion through capillary tube system

○ Filter on the liquid line

○ Cold room light and bulb

○ Cable for door micro switch

○ Cable for door switch heater on low temperature units

○ High- and low-pressure switches

○ Remote electronic control panel

OPTIONAL ACCESSARIES AND CONFIGURATION.

Power supply:

230/1~/50

400/3N~/50

208-230/1~/60

230/3~/50

208-230/3~/60

440-460/3N~/60

440-460/3~/60

108-115/1~/60

Electrical accessories:

Prearrangement for supervision system

Accessories kit:

Audible and visual alarm

Remote control panel for 2-3-4 units

Condensation type:

Air + Axial Fan

Air + Centrifugal fan

City water with pressure valve

Winter Kit, low ambient temperature accessories:

Crankcase heater + Condenser fan pressure switch +

Double solenoid valve for defrosting

Crankcase heater + Pressure controlled condenser fan

speed regulator + Double solenoid valve for defrosting